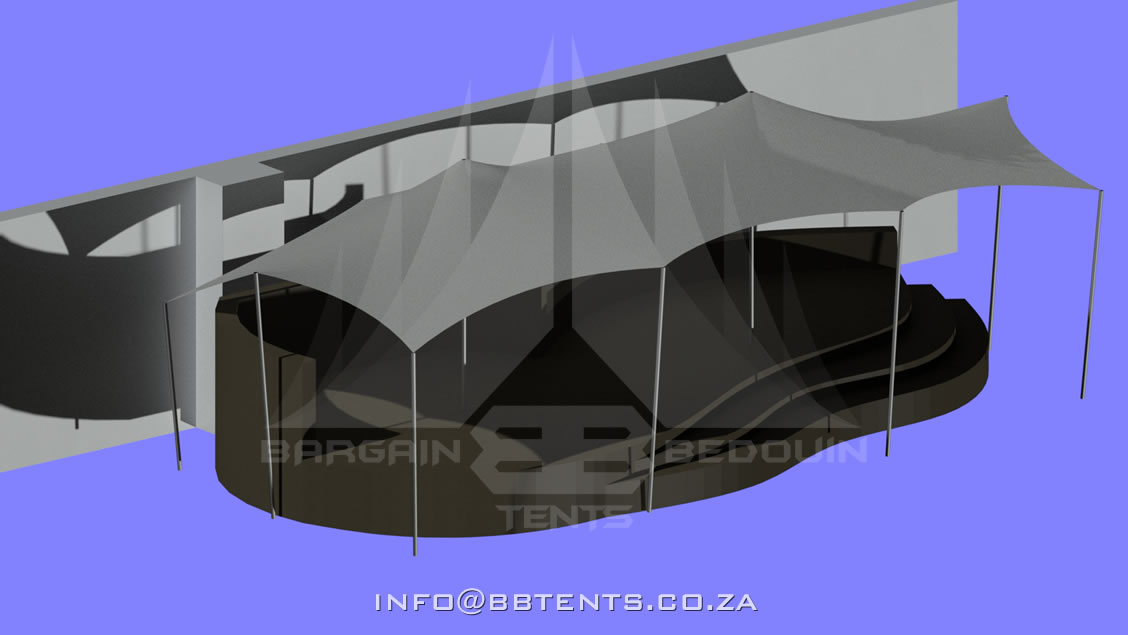

Permanent Engineered Structures

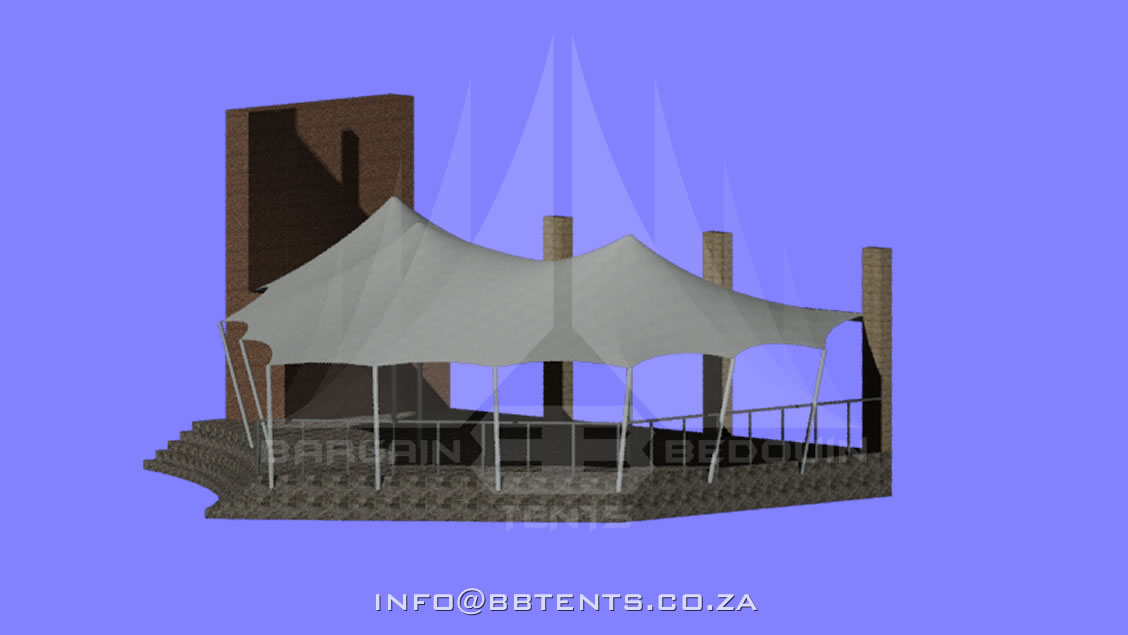

We design, engineer, manufacture and install High Tensile Fabric Structures suitable for permanent construction projects. These structures are mainly aimed at public areas in the retail and hospitality industry. We offer a range of pre-engineered designs of high tensile structures. We provide total custom design solutions to selective clients in search of quality structures and professional service, backed with our long industry experience. From concept to completion, we obsess over every fine detail, ensuring that the final product meets and exceeds the expectations of the final resulting structure.

We offer existing building owners professional and comprehensive site inspections, conceptualisation and 3D design during the quoting phase. We offer an annual structure and membrane maintenance program, including membrane replacement, structural additions, upgrades and general maintenance.

High Tensile Structures

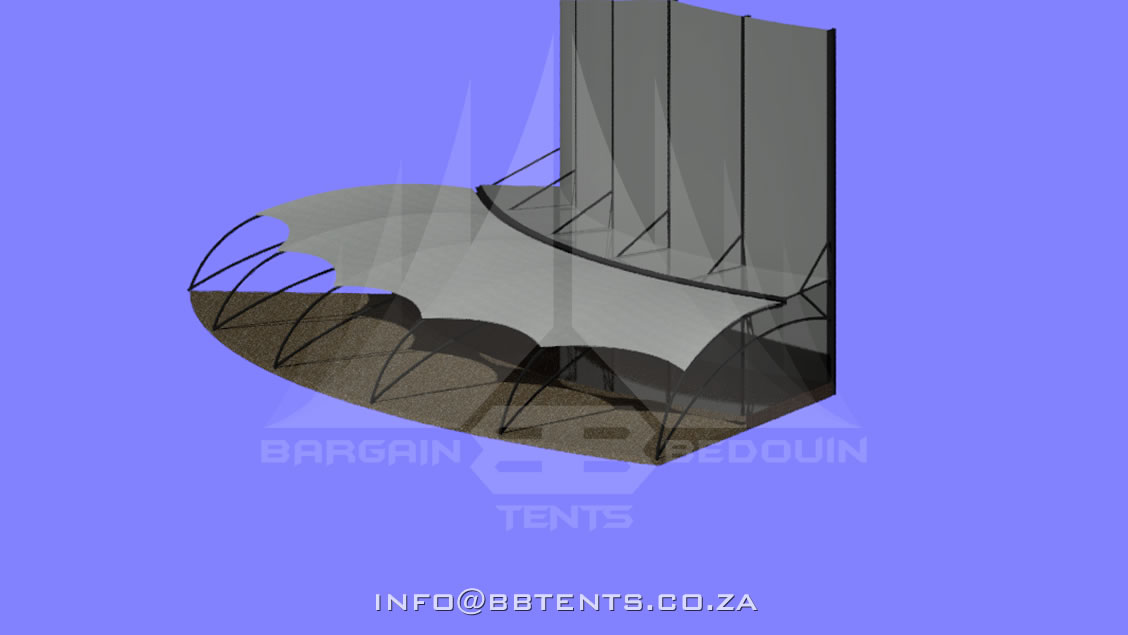

Architectural grade tensile structure with cable and/or steel frame, with supported tensioned membrane-covered PVC fabric; incorporating a fabric with low elongation characteristics under tension and capable of an anticlastic configuration.

BB Tents tensile structures are engineered to last, utilising architectural grade PVC membranes & custom engineered steel work. PVC membrane fabric canopies are a cost-effective alternative to traditional roofing or façade systems and can be produced in a multitude of colours to coordinate with individual building project needs. High tensile canopies, awnings, umbrellas and sails have a minimum life expectancy of 10 years on the membrane, and lifetime warranty on the structural steel work.

Benefits of architectural membrane structures

DESIGN

Our engineers and designers will work closely with your team to identify the practical and aesthetic requirements of a project.

ENGINEERING

BB Tents engineers craft and mould ideas into reality, by utilizing the most modern and sophisticated software available.

FABRICATION

BB Tents have experience in custom steel work, custom fabric patterning and conversions, exploring the most innovative design, engineering and manufacturing techniques.

BUILD

BB Tents have highly skilled specialty installers to erect these complex tensile structures from the ground up.

Applications

Ready to find out more?

Drop us a line today for a free quote!